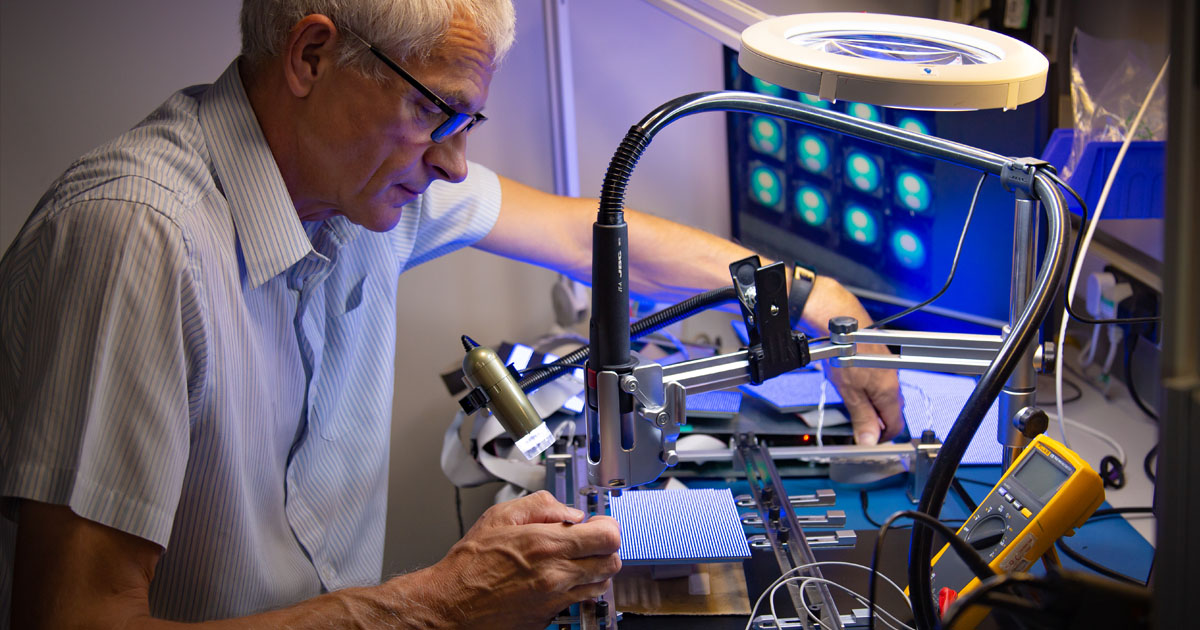

A solder and steady hand kind of guy.

Why people like Steve Haydon still matter to AV.

Perhaps we should learn to let it pass. Perhaps there are bigger and more important things to worry about in the world. But there is nothing, nothing, with the potential to jangles the nerves of an AV professional more than the sight of dead clusters on an LED screen.

Like ants in a sugar bowl

When this is your job, when this is what you do, each black blemish mocks you like an ant in a sugar bowl and suddenly all the sweetness is gone.

Flaws like these don’t belong here, not when so much time has been spent on the content, on alignment, on getting the perfect image perfectly displayed. Not when this cutting edge, expensive, tech promises so much and the results of your hard work will be seen by so many.

But as pitches decrease and bezels narrow it is hard to make sure each panel is installed unscathed – no matter how perfect they were when they left the production line. Dead clusters, it seems, are a burden we must grin, bear and try to ignore. True, you can swap out the entire module, but different LEDs from different batches look, well, different. Chances are the entire module will look out of place – do it often enough and the dreaded LED chequerboard effect appears.

And that’s why, in a quiet corner of Christie EMEA’s hi-tech workshops, you’ll find Steve Haydon and people like him.

From the exact same manufacturing batch

An old-school, solder and a steady hand kind of guy, Steve has the skill to replace dead LEDs on Christie panels cluster by cluster – by hand and from the exact same manufacturing batch. By the time his work is complete, the modules are visually indistinguishable from the originals. The ants have left the sugar bowl, everything is sweet once again.

Working through a microscope, with liquid solder, flux paste and seemingly infinite patience he can repair even the finest pitch modules – and the microscopic conductive tracks on the PCBs themselves. You may have imagined that these manual skills had long ago lost their attraction, but at Christie EMEA’s recent open day, where the range of tech on display was mouth-watering, it wasn’t only the room temperature RGB projection and the latest SDVoE compliant kit that held the visitors in awe. So did Steve Haydon – quietly and consistently achieving the seemingly impossible.

It’s people that make it work

That’s one of the charming things about our industry. It loves new technology and delights in what it can achieve, but it never loses sight of the fact that it’s people – like Steve Haydon – that make it work. And their skills can never be wholly redundant if we hope to get the best from our tech.

Without the people who create content, to the techs who link it all together, to the men and women who work and plan late into the night, even the best products in the world may as well stay in their boxes.